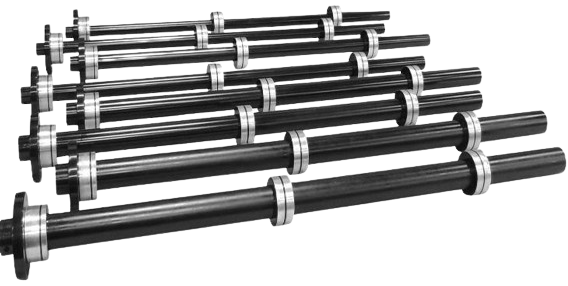

Spindle Liners

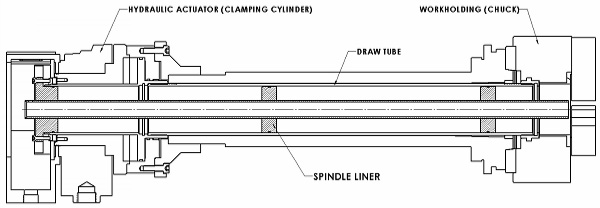

Spindle Liners (also referred to as filler tubes, reduction tubes, master liners or sleeves), are used to reduce the I.D. of a CNC Lathe spindle. Clearance is application and material dependent, but usually they are sized to 0.030″-0.060″ over the diameter of the bar being machined.

The result is faster machining speeds and closer machining tolerances. Spindle liners are used in lathes often in conjunction with bar feeders, bar loaders, baster supports and bar pullers.

The JF Berns Company manufactures the best quality spindle liners in the industry.

Best Quality, Fastest Deliveries!!

Ready to Use

Size and Part Number

Safe

Experience

We are the industry leader with over 40 years of experience and with a database of over 100,000 spindle liners manufactured. More experience, less problems!

Increase Lathe Bar Length Capacity

Extended Spindle Liners will allow for a longer bar to be run in the lathe. If the extension is longer than the coolant collector, we can also provide the coolant collect or extension.

- Longer bar = less material waste

- Fewer cuts on 12′ bars

- Fewer remnants

- More efficient bar feeder use

- Bridge gap between bar feeder and spindle

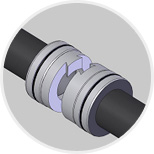

Easy Out System

Quick Change Spindle Liners

This will automatically lock the liner in place. To remove the liner, just pull the spring loaded pin and reverse the procedure. Each CNC lathe will require the purchase of one quick change adapter.

To find out more on when to use metal spindle liners vs. urethane spindle liners, CLICK HERE.

Our extensive database of machine data for spindle liners includes models from these lathe manufacturers:

Ace, Aero, Alpha, Amera Seiki, Buildwell, Chandox, Chia Her, Chiron, Citizen, Clausing, Cybertec, Daewoo, DMG, Doosan, Emco Maier, Eurotech, Fortune, Ganesh, Gildemeister, Haas, Hainbuch, Hanwha, Hardinge, Hitachi Seiki, Howa, Hurco, Hwacheon, Hyundai, Index, Johnford, Khan, Kia, Ksi, Leadwell, Matsumoto, Mazak, Mighty, Miyano, Monarch, Mori Seiki, Nakamura Tome, Nexturn, Nomura, Okuma, Riken, Rohm, Romi, Samchully, Star, Strong, Suhner, Takamaz, Takisawa, Tonfou, Traub, Tsugami, Wasino, Willemin-Macodel, Yama Seiki, YCM, Supermax, YCI and more!