Metal

Spindle Liners

HIGH QUALITY

DESIGN & MANUFACTURING SINCE 1983

PRECISION CHAMFERING MACHINES

SERVO AUTO CHAMP

PRECISION CHAMFERING MACHINES

BAR CHAMP

CNC TOP LOAD BAR

SUPPORT

SUPPORT

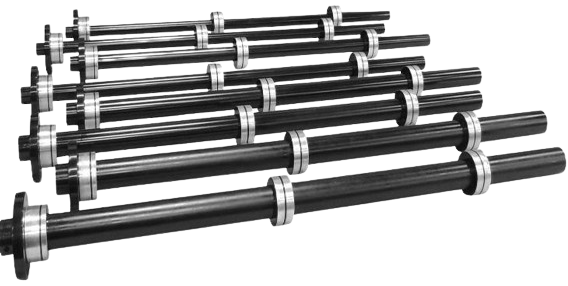

METAL

SPINDLE

LINERS

SPINDLE

LINERS

DOUBLE

ENDED

CHAMFERING

MACHINES

ENDED

CHAMFERING

MACHINES

HIGH QUALITY

DESIGN & MANUFACTURING SINCE 1983

PRECISION CHAMFERING MACHINES

SERVO AUTO CHAMP

PRECISION CHAMFERING MACHINES

BAR CHAMP

CNC TOP LOAD BAR

SUPPORT

SUPPORT

METAL

SPINDLE

LINERS

SPINDLE

LINERS

DOUBLE

ENDED

CHAMFERING

MACHINES

ENDED

CHAMFERING

MACHINES

JF BERNS PROUDLY SUPPORTS

ABOUT JF BERNS COMPANY

Why Work With Us

The J.F. Berns Company, located in Cincinnati Ohio, has been in business since 1983. Since that time we have specialized in barfeed and lathe accessories and Chamfering Equipment.

The company and our product lines have grown from our expertise, experience and reputation in the metal working industry. Our commitment is to quality products in a timely manner as well as continual improvement and innovative solutions.